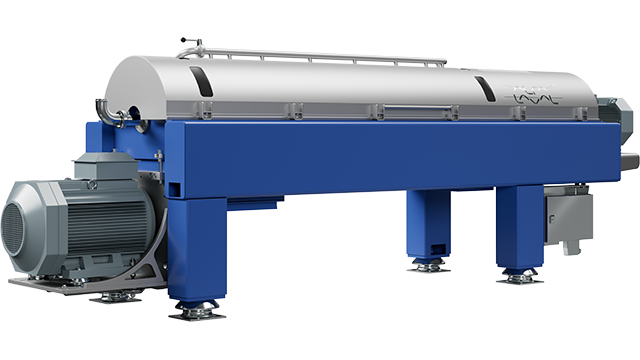

Prodec

Maximize separation performance with Alfa Laval Prodec decanter centrifuges—a reliable and cost-effective solution for demanding processing operations. Engineered for endurance and efficiency, these industrial centrifuges set the benchmark in advanced solid-liquid separation. Prodec decanters are your trusted separation equipment for a broad range of industries, including mineral processing, battery recycling, ethanol, biofuels, chemical production and starch dewatering.

Experience superior solid-liquid separation efficiency with Alfa Laval Prodec decanter centrifuges

- Maximize product recovery in demanding industrial applications through continuous, uninterrupted operation

- Compact design with high throughput delivers robust processing capacity within a small footprint

- Advanced conveyor technology enables precise control over separation, improving consistency across varying feed conditions

- Durable engineering with optimized materials for reliable performance even in erosive, corrosive and high-temperature environments

- Smart cleaning powered by Alfa Laval’s integrated control technology reduces downtime and extends the life of your decanter equipment

Improving energy efficiency with advanced centrifuge design

The bowl can be equipped with special power plates or tubes that harness the hydraulic energy to reduce the overall power consumption. Some of the discharge velocity from the liquid leaving the unit is captured and re-directed to contribute to bowl rotation. This reduces the velocity of the discharged liquid, which in turn reduces overall power requirements. The unique Alfa Laval direct drive system automatically controls the conveying speed to ensure optimum solids dryness, irrespective of acceptable variations in the feed flow.

Which decanter features make a difference in your industrial separation process?

Available as 2 or 3-phase designs, our Prodec decanter centrifuges can be tailored to specific requirements using options such as enhanced wear and corrosion protection, duplex or super duplex stainless steel for parts contacting process media, and different elastomers and seals. Prodec decanters can also be specially sealed and purged. The bowl and conveying speed, pond depth in the bowl and feed rate are adjustable to support optimum performance to operate more reliably and more efficiently – even at centrifugal forces as great as 3,500 G. We also cater for ATEX Zone 2 as well as Zone 1 with inert gas purging on case-to-case basis.

The back drive features a direct drive gearbox, a unique Alfa Laval system for automatically controlling the differential speed between the bowl and the conveyor. This makes it easy to maintain the best possible balance between liquid clarity and solids dryness, irrespective of variations in the feed. It also results in big savings in energy. And since the pinion shaft only turns in one direction, the unit is also much easier to control than with traditional methods.

The Prodec decanter centrifuge comes with an Alfa Laval decanter automation control package as standard, pre-installed and factory-tested to make sure you get the most out of your set-up. It also helps minimize costs for installation, commissioning, operation and maintenance.

3Phase

3Phase

Separating suspended solids from two liquid phases in one step

Accurate adjustment possibilities and long retention time ensure separation in three distinct fractions in one run. 3Phase ensures an accurate and stable interphase level, which is key for coping with variations in feed compositions and flow rates. The unique design creates low agitation, resulting in high clarity in both liquid phases.

DeepPond

Hohe Abscheideleistung und Energieeffizienz

Durch die Vergrößerung der Teichtiefe innerhalb der Trommel wird ein größeres Volumen geschaffen, was zu einer längeren Verweilzeit und einer verbesserten Trennleistung führt. Das DeepPond-Design sorgt für einen hohen Feststofftrockengehalt und sauberes Zentrat aus Ihrer Dekanterzentrifuge, selbst bei hohen Durchflussraten.

VecFlow™

Rotierende Einzugszone

Low turbulence in the decanter centrifuge bowl is essential for high separation performance and low power consumption. The VecFlow™ rotating feed zone gives you maximum performance with minimal turbulence.

OilPlus

Maximierte Ölgewinnung

Spezielle Wechselwirkung zwischen Feststoffen und Flüssigkeiten für eine maximale Ölausbeute.

FlightGuard

Robuster Verschleißschutz für Förderbänder

Der FlightGuard-Verschleißschutz besteht aus an das Förderband geschweißten Kacheln, die für robuste Verschleißfestigkeit und längere Betriebszeit bei Anwendungen mit hohem Abrieb sorgen.

How do Alfa Laval Prodec decanter centrifuges work?

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The product is fed into the bowl through a stationary inlet tube and is then smoothly accelerated by an inlet rotor. Centrifugal force immediately makes the solids build up on the wall of the bowl.

The conveyor rotates in the same direction as the bowl, but at a different speed. This moves the solids towards the conical end of the bowl, where they exit through the solids discharge openings into the casing. Separation takes place along the entire length of the cylindrical part of the bowl, and the clarified liquid leaves the bowl by flowing over adjustable plate dams into the casing.

Prodec decanter service

With our Global Service Network, help is always close at hand. No matter where or when you need us, we keep your Alfa Laval decanter centrifuge running at peak performance—giving you more uptime and complete confidence for the life of your equipment.

Let us help you

Our industry experts are readily available to collaborate with you in identifying opportunities and evaluating challenges, providing unique solutions that accelerate results and optimize your return on investment.