Chemikalienrückgewinnung

Recovering valuable chemicals and by-products from mill processes is an easy, straightforward way to raise profitability at your mill. Alfa Laval offers a broad range of equipment for separation equipment to help you do just that.

Recovery of valuable chemicals and

by-products

The global decline in paper production is forcing chemical pulp mills to cut costs and identify new revenue streams. Chemical recovery and extraction of by-products plays a key role in these efforts. Separating substances of value from the process streams for onward sales or reuse is a smart way to boost profitability.

Continuous, energy-efficient recovery of valuable chemicals

Recovering valuable substances from process streams requires energy, resources and mill floor space. Consider what reducing the total cost of operations could do for your mill. Alfa Laval decanter centrifuges do just that.

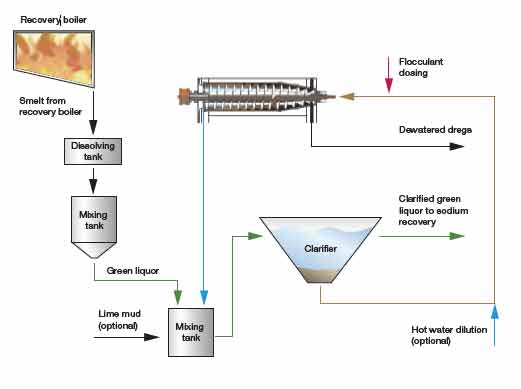

Take the process of dewatering sludge, such green liquor dregs. A smart alternative to traditional rotary vacuum filters, Alfa Laval decanter centrifuges use far less energy, take up 80% less floor space, don’t require additional lime or complex utility equip¬ment such as vacuum pumps and pre-coating systems. What’s more, our highly reliable automatic decanters provide continuous operation, reducing process waste streams into an easy-to-dispose-of highly dry cake, drastically cutting disposal costs while boosting chemical recovery.

Process overview

Benefits

- High chemical recovery

- Reduced installation, operating and maintenance costs

- Low sludge disposal costs

New revenue streams from by-products

Profit from extracting and selling high-purity chemical by-products using proven Alfa Laval separation technologies. With Alfa Laval’s solutions, you can separate these valuable chemical compounds from mill process waste streams:

Turpentine – Alfa Laval’s highly efficient condensers let you extract turpentine from digester fumes using minimal amounts of cooling water.

Lignin – Our membrane filters enable you to extract lignin from black liquor with minimal operating costs.

Hemicellulose and nanocellulose – High quality recovery of hemicellulose and nanocellulose is both easy and cost-effective using Alfa Laval membrane filters.

Lignosulphonate – Our fully automated membrane filtration solutions also offer a low-cost method to recover lignosulphonate from spent sulphite liquor.

Green liquor dregs dewatering

Södra Cell is one of the world’s leading manufacturers of market pulp. Learn how they reduced chemical losses in green liquor dregs with an Alfa Laval decanter centrifuge.

Alfa Laval experience makes the difference

BIOTECH Paskov produces lignosulphonate extracted from spent sulphite liquor, and is used by the building industry, metal industry, paper and board manufacturers. Alfa Laval has supplied plate-and-frame membrane modules.