Rohölraffinerie

Hohe Effizienz, niedrige Kosten und der Fokus auf Nachhaltigkeit sind kritische Faktoren, um in der Ölraffinerieindustrie wettbewerbsfähig zu bleiben. Mit den Alfa Laval Lösungen für Raffinerien verbessern Sie die Rentabilität und gewährleisten maximale Zuverlässigkeit und Produktqualität. Werden Sie unser Partner und profitieren Sie von unserer Erfahrung und unserem Know-how. Mit Ihren Verfahrenstechniker*innen erarbeiten unsere Expert*innen Lösungen, die Ihre Raffinerie transformieren werden.

Services zur Prozessoptimierung

Sie haben es sich zum Ziel gesetzt, die Effizienz in Ihrer Raffinerie zu verbessern? Unser Expert*innen-Team hat seine hervorragende Arbeit bereits in zahlreichen Anwendungen rund um den Globus unter Beweis gestellt. In der Galerie finden Sie einige unserer interessantesten Beispiele.

Erfahren Sie mehr über unsere Services zur Prozessoptimierung

Maximale Prozesseffizienz

- Höhere Produktionskapazität

- Verbesserter Produktertrag und gesteigerte Produktqualität

- Höhere Energieeffizienz

- Verbesserte Zuverlässigkeit

- Niedrigere Lebenszykluskosten

Minimaler Projekt-CAPEX

- Niedrigere Kosten für Prozessanlagen

- Vereinfachte Prozesskonfiguration

- Reduzierte Installationskosten

- Optimale Lösungen für modulares Design

Nachhaltigkeit

- Geringerer Energieverbrauch

- Reduzierte Emissionen

- Minimaler Kühlwasserverbrauch

- Geringerer Materialverbrauch

Lösungen

Ihre Prozesse überdenken

Die Alfa Laval Lösungen für Raffinerien bieten viele neue Möglichkeiten, um die Betriebseffizienz Ihrer Anlage zu verbessern, die Investitionskosten für neue Investitionen zu senken und Ihren ökologischen Fußabdruck zu minimieren. Wir haben Raffinerien auf der ganzen Welt geholfen, vielfältige Prozesse zu optimieren.

Anlagen überdenken

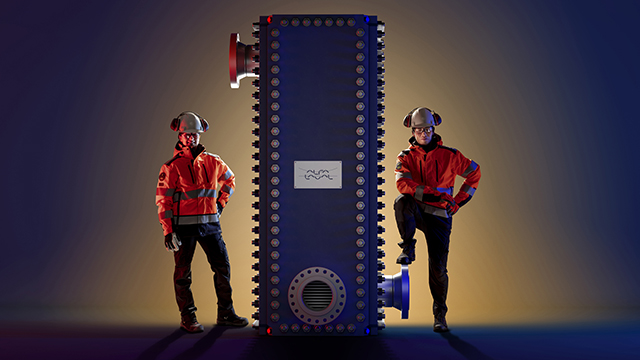

Alfa Laval bietet eine breite Palette von Produkten an, die sich durch hohe Effizienz und Zuverlässigkeit auszeichnen und optimal für den Einsatz in Raffinerien eignen. Dank unserer langjährigen Branchenerfahrung wissen wir genau, wie wir Lösungen entwickeln, die die Leistung und die Zyklusdauer Ihrer Prozesse maximieren.

Services überdenken

Wir unterstützen Sie mit Services und Schulungen aller Art, die für eine hohe Leistung und maximale Rendite während der gesamten Lebensdauer Ihrer Investition erforderlich sind. Alfa Laval als Servicepartner – das ist Ihre Versicherung für verlässliche Betriebszeiten und hohe Effizienz bei minimalen Gesamtbetriebskosten.

Geschichten und Artikel

Erfahren Sie, wie das Alfa Laval Raffinerieteam zur Prozessoptimierung in zahlreichen Raffinerien auf der ganzen Welt beigetragen hat. Mit unseren bewährten Lösungen helfen wir Ihnen, die Rendite Ihrer Raffinerieinvestitionen zu maximieren, ganz gleich ob Sie eine Modernisierung oder eine neue Anlage planen.

Webinare

Wie können Sie mehr aus den Raffinerieprozessen herausholen und gleichzeitig weniger Energie aufwenden? Am Beispiel der Rohöldestillation und der Naphtha-Hydrobehandlung zeigen unsere Expert*innen die Möglichkeiten auf – und eine Vorstellung davon, wie viel Sie sparen könnten.

Nachhaltige Lösungen

Stellen Sie sich eine nachhaltigere Welt vor. Eine Welt, in der man weniger braucht, um noch mehr zu produzieren. Eine Welt, in der wir unseren wachsenden Energiebedarf effizient decken und gleichzeitig die CO2-Emissionen reduzieren. Stellen Sie sich eine Welt vor, in der wir die Kraft der natürlichen Ressourcen nutzen und sie gleichzeitig schonen können. Bei Alfa Laval stellen wir uns diese Welt nicht nur vor. Wir bauen sie auf – gemeinsam mit unseren Kunden und Partnern.

Optimale Prozessgestaltung

Erfahren Sie von Eva Andersson und Wivika Laike von Alfa Laval, wie Sie mit unseren Lösungen die Rentabilität und Nachhaltigkeit Ihrer Raffinerie steigern können.

Optimieren Sie Ihre Kondensationsdienste

Unsere neuen Lösungen können Ihnen helfen, enorme Einsparungen zu erzielen und die Leistung in Ihrer Raffinerie zu verbessern. Sie ermöglichen es auch, einen Großteil der minderwertigen Energie zurückzugewinnen, die andernfalls verschwendet würde.

Downloads

Treffen Sie uns

Dokumente

Artikel

Weitere Möglichkeiten, schnell mit uns in Kontakt zu treten:

Alfa Laval Mid Europe GmbH

Wilhelm-Bergner-Straße 7

D-21509 Glinde

Germany

Telefon: +49 40 72 74 20 20

E-Mail: info.mideurope@alfalaval.com

News zu Alfa Laval Energy auf LinkedIn

Erfahren Sie, was unsere Lösungen und unsere Unterstützung als Partner dazu beitragen können, neue Möglichkeiten zu finden, um mehr aus bestehenden Prozessanwendungen herauszuholen, und wie wir Ihrem Unternehmen helfen können, auf die richtige Weise zu wachsen – indem Sie Ihr gesamtes nachhaltiges Potenzial ausschöpfen. Unsere Showcase-Seite hält Sie über unsere neuesten Innovationen und Lösungen sowie über unsere Arbeit in den Bereichen saubere Energie, Energieeffizienz und Kreislaufwirtschaft auf dem Laufenden.

Sparen Sie Energie – von Anfang bis Ende!

Profitieren Sie von der jahrzehntelangen Erfahrung von Alfa Laval in der Zusammenarbeit mit EPC-Projekten und Ihren Endkunden. Wir können Sie während des gesamten Projekts unterstützen, um sicherzustellen, dass Ihre Kunden das optimale Wärmetauscher-Paket erhalten.