Industrial water use and reuse

We have so much water around us, yet so little we can use. In the world of industries, Water it is an energy carrier, an enabler for production and carrier of valuable by products. It also helps to cools down our industries. However, with climate change and growing population driving demand, fresh water is becoming increasingly scarce. Today, only 5% of all industrial water is recycled.

Why is it important to have a sustainable water management?

Water scarcity can disrupt your supply chain, impact production, and even force you to shut down operations. Even if your business is located in water-rich regions, sustainable water management is essential, as legislation can restrict or halt capacity extension and new operations. That is why it is crucial that we find a way to optimize the use, reuse, and cleaning of water.

Water is a critical component in the energy transition

Sustainable water management is a critical component in the net zero transition, and industries such as mining, renewable energy, recycling and data centers are just some examples of industries that require large amounts of water.

Green hydrogen

Sea water can be used as a source, and through desalination generate the needed fresh water.

Process industry

Wastewater can be reused inside the process up to 98 %, minimizing the waste and fresh water intake.

Data centers

Efficient cooling will reduce or even remove the need of water for cooling purposes.

Mining

Efficient water and waste management can reduce tailings volumes, save space and increase the recovery of water, chemicals and minerals.

Ground engineering

Water management is key in excavation and foundations, in cooling machines, maintaining pressure, moving solids, or as a means of cleaning.

Mineral exploration

Reliance on fresh water can be reduced through a closed-loop system where water can be circulated back to the drill-rig when water is scarce or hard to access.

Recycling

Treat complex wastewater to reduce disposal cost and meet discharge limits. In addition, you can recycle water from the waste stream back to your process and sometimes even to recover valuable by-products.

Renewables

Converting renewable feedstock into chemicals, fuels and plastic produces large amounts of washing wastewater. By treating this stream, it is possible to recover water back to the process, recover value from the waste and reduce disposal costs.

Solutions that enable sustainable water management

There are already existing and proven solutions today that can secure your future operation, discover some of the examples.

Safeguarding water supplies

We can secure the availability of fresh water by eliminating unnecessary fresh ground or surface water use. For example, our solutions make it possible to distil and use water from the sea and rivers instead of taking valuable fresh water in certain industries. Additionally, Alfa Laval’s solutions enables the reuse of water and make sure that you have the right quality for your purposes without impoverishing our natural resources.

Water as value

Alfa Laval’s equipment makes it possible for you to secure a circular water system and run your operations without interruption. By cleaning and reusing water, you can limit the amount of fresh water that enters your plant and reduce or even eliminate wastewater.

Reduce your water usage by cleaning and reusing it in your process or sell it on.

Water as waste

Treat your water on site so that you can safely return it to the eco-system. Alfa Laval’s equipment helps you secure a balanced water withdrawal with efficient handling of effluents in compliance with current regulations.

Water purification for green hydrogen production

Accelerating water circularity at Tecnoparco Valbasento

Compact and user friendly waste and water treatment in mineral exploration

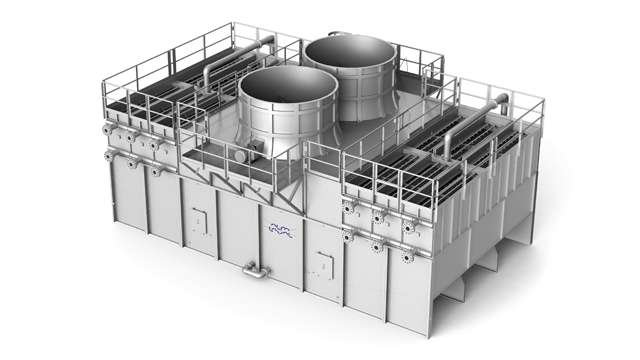

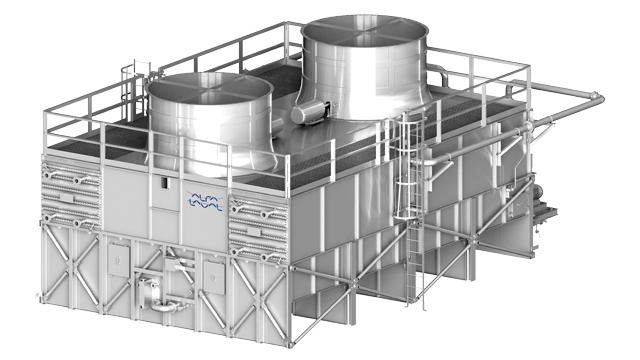

Product offering

Alfa Laval offers a wide range of products to optimize the use, reuse, and cleaning of water across industries.

Water scarcity

Water scarcity is intensifying around the globe and is affecting both industries and individuals. The increasing population and subsequent rise in demand is putting significant pressure on fresh water sources, which are already impacted by the climate crisis. In fact, even though we are living on a blue planet, less than 0.02% of our water resources are currently available and accessible for the entire planet to use in industrial operations. In industries like renewable chemicals, manufacturing, and recycling industries that consume large amounts of water, this poses a serious threat. The responsible way forward for both industry and individuals is to care about and reuse the water that we have.

What causes water scarcity?

Water scarcity is caused by climate change, overpopulation, and today’s consumer lifestyle. Many industries also use water in their process.

How do we solve water scarcity?

The solution to our water scarcity issues is to close the water loop by reusing what we consume. Here at Alfa Laval, we use well known and tested technologies to make it possible to reuse industry wastewater and clean water to return back into the eco-system. We also provide solutions that make it possible to distil and use water from the sea and rivers instead of taking valuable fresh water in certain industries.